*NOW BOOKED FOR 2025* Transitmania 16 @ Santa Pod 11th to 13th July 2025 *ALL DETAILS HERE*

My Mk1 Transit's Restoration Project

Re: My Mk1 Transit's Restoration Project

good looking work going on there.filler should be ok as long as it is sealed properly afterwards.

- irishtransit

- Transit Devotee

- Posts: 548

- Joined: Sat Jan 12, 2008 11:41 pm

- Location: mallow county cork ireland

Re: My Mk1 Transit's Restoration Project

Keep up the good work

Ketil

Norway

Ketil

Norway

Ketil

Norway

ketil.frengen@norgespost.no

2,9 Cosworth V6 1968 mod LWB Twin wheeler

viewtopic.php?f=27&t=49610

Norway

ketil.frengen@norgespost.no

2,9 Cosworth V6 1968 mod LWB Twin wheeler

viewtopic.php?f=27&t=49610

-

spitfire - Transit Aficionado

- Posts: 186

- Joined: Tue May 06, 2008 8:31 pm

- Location: Gjøvik NORWAY

Re: My Mk1 Transit's Restoration Project

Gerald just an advice; I dont think the filler would be a problem, but to fill holes like those , keep the mig gun further away from the metal, so the resistance the welding wire will offer is more, so smaller current. It will come ugly welding but in that way you will bulid up the hole, then the grinder should do his work

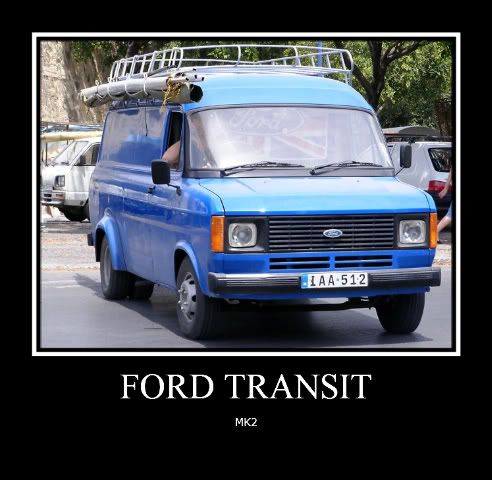

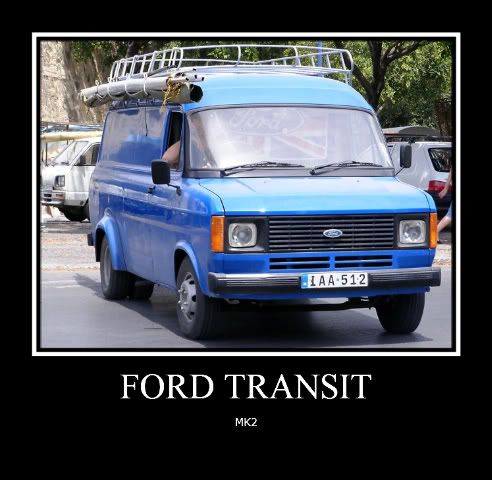

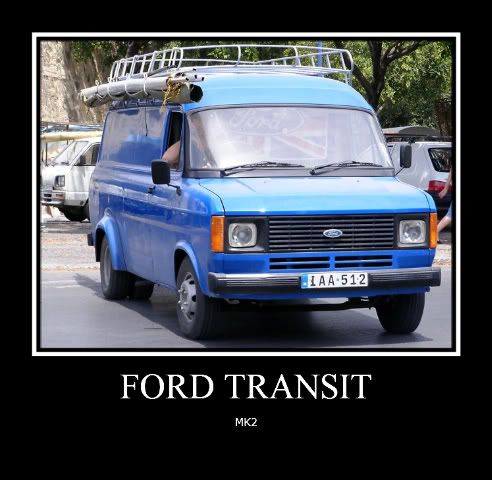

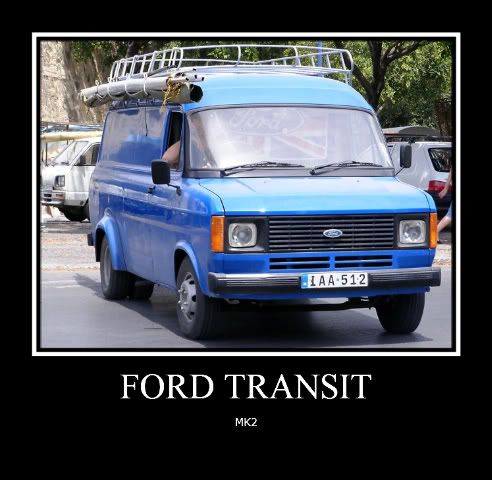

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Re: My Mk1 Transit's Restoration Project

Thanks mates

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

Just a quick tip on filling them small holes with a mig. Split a length of copper plumbers pipe and flatten out into a thin plate. Make sure you have enough to cover the hole. Place on the opposite side to which you are going to weld, wedge in for a tight fit so that the copper is pressed hard up against the hole. Now fill the hole up with the mig starting on the copper plate working towards the edge of the hole to plug it. Then grind back weld smooth. On the back the copper has fused to the weld so might need to be ground off.

The idea of the copper is to absorb the heat away from the weld, hence not blowing a hole through the panel. Then you know what happens, you start chasing holes.

Have restored a few volkswagens in the past and has worked a treat. One last thing, if the panel is like a perforated tea bag and thin, above method will not work. Better renew with new metal.

Hope this helps, and glad to see another old motor back on the roads, keep up the excellent work.

Cheers

VEEMAN

The idea of the copper is to absorb the heat away from the weld, hence not blowing a hole through the panel. Then you know what happens, you start chasing holes.

Have restored a few volkswagens in the past and has worked a treat. One last thing, if the panel is like a perforated tea bag and thin, above method will not work. Better renew with new metal.

Hope this helps, and glad to see another old motor back on the roads, keep up the excellent work.

Cheers

VEEMAN

- VEEMAN

- Transit Addict

- Posts: 55

- Joined: Thu Dec 11, 2008 8:05 am

Re: My Mk1 Transit's Restoration Project

Thanks VEEMAN, that's a very new good idea to me. I had seen brasing on small holes done on to my car by a panel beater,but haven't seen him doing it. I should try it,though in that particular place there's another body part which can't be acssesed.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

veeman great tip that worth keeping in mind!

- madmark

- Transit Extremist

- Posts: 15467

- Joined: Thu Mar 03, 2005 4:29 am

Re: My Mk1 Transit's Restoration Project

Back again, I started cutting the passenger side step. Where the splash panel was and outrigger was,they became perforated teabags  so i cut off the step.

so i cut off the step.

And took away the rusty chassis leg off. At this time i bought a drill bit to drill off spot welds which helped me alot. I also attached it to a flexi cable which i can enter places that the drill couldn't.

I cut off the end of the wheel panel and also a part of the floor;

Then put new metal in and welded;

Then I linished it off for a smoth surface.

And took away the rusty chassis leg off. At this time i bought a drill bit to drill off spot welds which helped me alot. I also attached it to a flexi cable which i can enter places that the drill couldn't.

I cut off the end of the wheel panel and also a part of the floor;

Then put new metal in and welded;

Then I linished it off for a smoth surface.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

Excellent thread - Keep Going!

- Southerner

- Transit Aficionado

- Posts: 199

- Joined: Fri Jul 15, 2005 12:16 pm

Re: My Mk1 Transit's Restoration Project

- madmark

- Transit Extremist

- Posts: 15467

- Joined: Thu Mar 03, 2005 4:29 am

Re: My Mk1 Transit's Restoration Project

Top Job Malta!

Glad to see you back in "business"

Glad to see you back in "business"

Still (t)rust in my Tranny

www.ztorm.nl

www.ztorm.nl

-

ztorm - Transit Aficionado

- Posts: 233

- Joined: Mon Mar 09, 2009 7:15 pm

- Location: Den Helder, Holland

Re: My Mk1 Transit's Restoration Project

glad ya back

- irishtransit

- Transit Devotee

- Posts: 548

- Joined: Sat Jan 12, 2008 11:41 pm

- Location: mallow county cork ireland

Re: My Mk1 Transit's Restoration Project

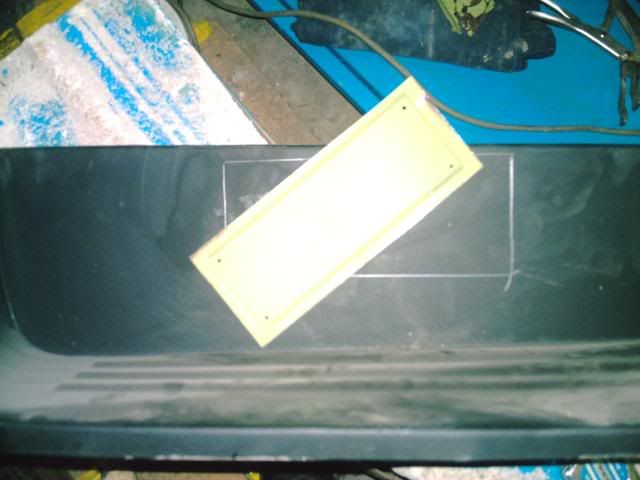

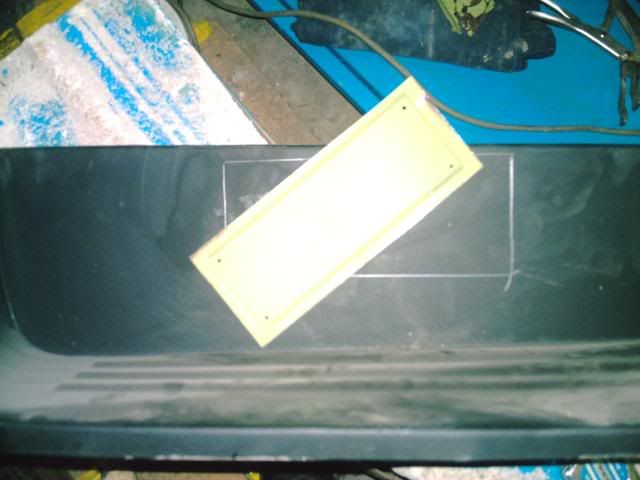

Today i just cutted the information back insert plate from the old step, as the reproduction step has no reeses.First i marked a rectangular on the old step then cut it out.

Then i marked the new step with the cut of bit which i'm going to use.

Then cut of the unwanted metal, and

Then welded the old plate in and linished it.

.

.

Then i marked the new step with the cut of bit which i'm going to use.

Then cut of the unwanted metal, and

Then welded the old plate in and linished it.

.

.TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

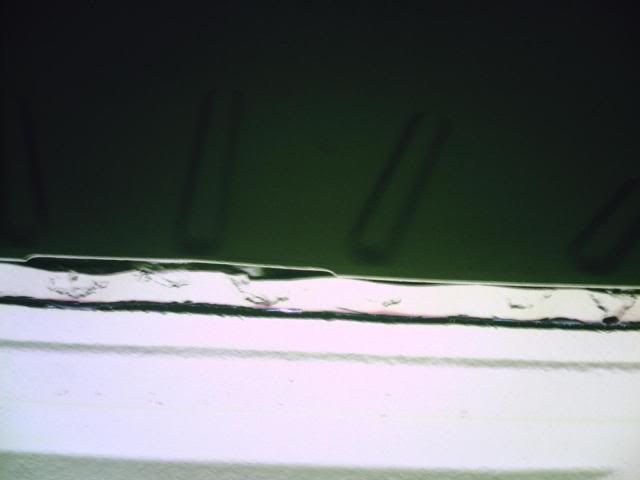

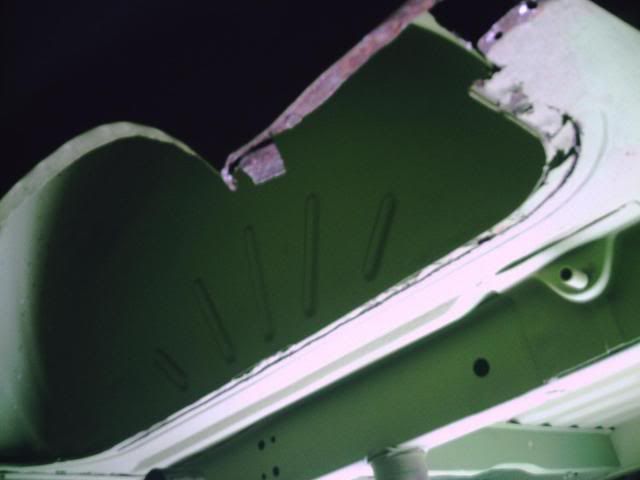

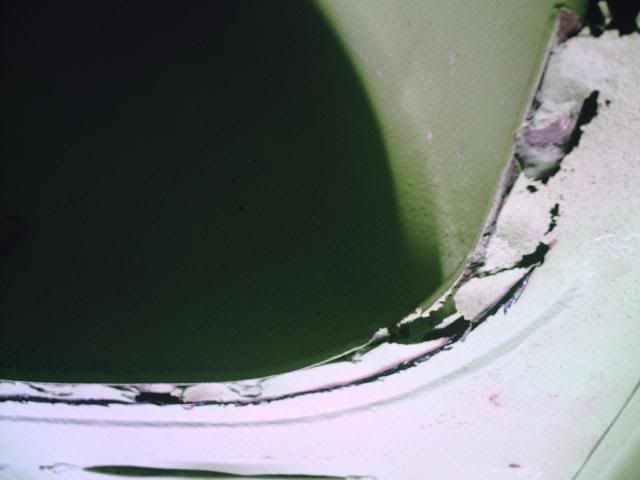

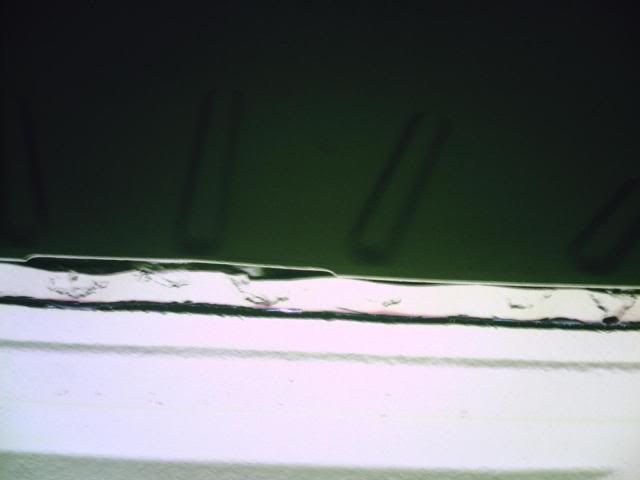

Hi, after seeing Madmark's Mk1, i found back my inspiration. last week i got back to my van and sitting on the floor started thinking how to tackle the side lower end panel. As one could see i tackled it quiet a few times, but now i decided to cut up more upwards and elimininate all the raw metal.

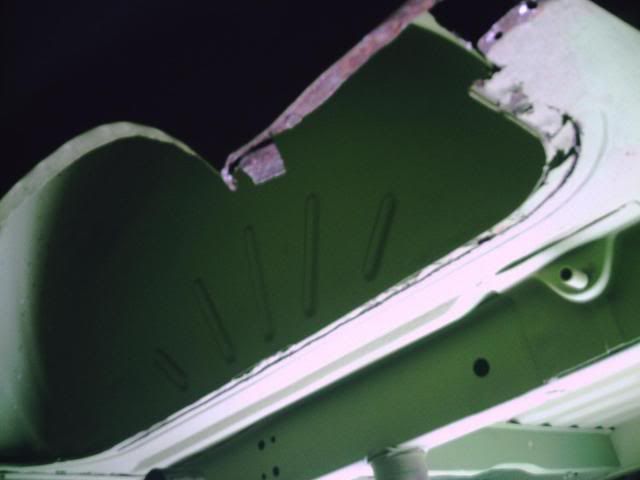

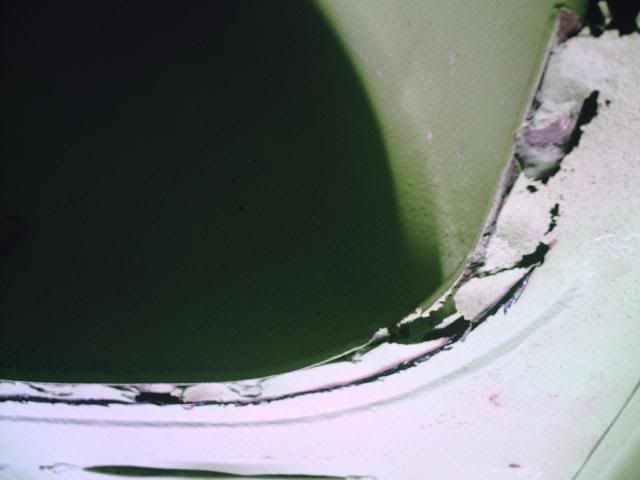

I drilled all the spot welds from the inner side floor and stated chisling the innerside metal out:

The veiw from outside. The metal which was spot welded to the outriggers were terrible to drill out as the spotweld drill bit has to be straight to drill, i could not drill them out not even with a flexi extation. At the end i cut out the metal in many parts with a chasser from the outer side. Then cleaned and grinded them flat.

After finishing this, I was going to measure the metal cut off to replace it, but realized that i had to do the lower inner wheel cover first. Where the bowl is spotwelded to the floor,rust has bodged up so i had to cut off the rot and clean well to put new meal inn first.

Cut and cleaned;

If i ll have chance this week, i ll try and see if i can weld in new metal.

I drilled all the spot welds from the inner side floor and stated chisling the innerside metal out:

The veiw from outside. The metal which was spot welded to the outriggers were terrible to drill out as the spotweld drill bit has to be straight to drill, i could not drill them out not even with a flexi extation. At the end i cut out the metal in many parts with a chasser from the outer side. Then cleaned and grinded them flat.

After finishing this, I was going to measure the metal cut off to replace it, but realized that i had to do the lower inner wheel cover first. Where the bowl is spotwelded to the floor,rust has bodged up so i had to cut off the rot and clean well to put new meal inn first.

Cut and cleaned;

If i ll have chance this week, i ll try and see if i can weld in new metal.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

- madmark

- Transit Extremist

- Posts: 15467

- Joined: Thu Mar 03, 2005 4:29 am

Return to Members Transit's - Progress Reports!

Who is online

Users browsing this forum: No registered users