*NOW BOOKED FOR 2025* Transitmania 16 @ Santa Pod 11th to 13th July 2025 *ALL DETAILS HERE*

My Mk1 Transit's Restoration Project

Re: My Mk1 Transit's Restoration Project

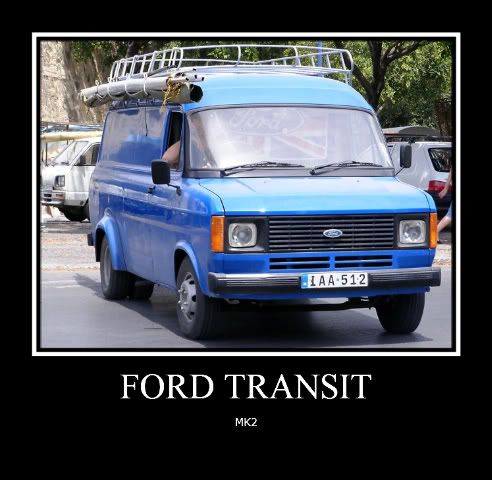

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Re: My Mk1 Transit's Restoration Project

Hi, today all i,v done is patterned this part below and welded it.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

For me it is very neat work

what type of welding are you using electric arch welding? Because im also interested in welding but im a beginer and mostly when I weld parts like that where the sheet metal is thin it creates melting holes. I m a beginer

what type of welding are you using electric arch welding? Because im also interested in welding but im a beginer and mostly when I weld parts like that where the sheet metal is thin it creates melting holes. I m a beginer

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Re: My Mk1 Transit's Restoration Project

Hi redeemer,i use mig welding. Its very easy to use just press the gun and the welding rod comes out as you press olso from the nozzel comes out co2 gas which flows the weld better + when ready you don,t need to chip the crust of the weld. The mig has a regulator to adjust the power of welding according to the thickness of the metal. Its good to invest in one. By the way I,m also a beginer and this is my first project, what i don,t have is time,as after work i m to tired to go in the garage. I work in a shop and shoping hours are long from 9.00 till 1.00 and 4.00 to 7.00. And 3/4 of the day i just read classic ford or retro ford.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

Thanks for the information !  Yes I have to buy a welding set like that before i can begin anything. I have the aceteleyne set with the welding burner which I find better than the electric one.

Yes I have to buy a welding set like that before i can begin anything. I have the aceteleyne set with the welding burner which I find better than the electric one.

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Re: My Mk1 Transit's Restoration Project

Today was another big task for me. I studied the footstep and after deciding how to cut,i cut out the step leaving an inch from the ends so i can spot weld the new replacement step to the remaining edge. The new panel step is not exsactly the same so i added missing bits of metal.

Then i trail fitted the new step several times and then drilled several holes to the step so i can spot weld it.

After, I measured the end of the A post and fabricated a new replacement, i cut the rusty one and welded the new one. After finishing i painted the new panels with zinc galvacoat, only were it can't be reached when fixed in place. If tomorrow i ll have some time i ll weld step in place.

Then i trail fitted the new step several times and then drilled several holes to the step so i can spot weld it.

After, I measured the end of the A post and fabricated a new replacement, i cut the rusty one and welded the new one. After finishing i painted the new panels with zinc galvacoat, only were it can't be reached when fixed in place. If tomorrow i ll have some time i ll weld step in place.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

Nice to see you progressing in your work  Well done you 're not a professional you work very neatly

Well done you 're not a professional you work very neatly

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Re: My Mk1 Transit's Restoration Project

good progress mate

you might want to quickly refit the door just loose, to check the door gap of the bottom sill before you fully weld it

when i did my pickup it looked ok untill i put the door on then i could see it was way out so i had to break the tacks and re do it

you might want to quickly refit the door just loose, to check the door gap of the bottom sill before you fully weld it

when i did my pickup it looked ok untill i put the door on then i could see it was way out so i had to break the tacks and re do it

-

Luke - Site Admin

- Posts: 44386

- Joined: Wed Mar 02, 2005 12:53 am

- Location: Rotherham, Yorkshire!!

Re: My Mk1 Transit's Restoration Project

You are right, Luke. I welded the 2 sides which have no adjusting and then could not get the A post side straight with the floor, because if i pushed up the front step up to meet the new original size, the step seemed to go up. So i measured the height from the top till the step, of the other side and it read 56inches so i marked 56" on the working step, and i realised I'm 1" less from my meeting point. To cut things short,after thinkering about, i realised that the new step is 1" lower than the original, so to have the correct lenght the top angle were it meets the A post it has to be slanting.From the photo below you can see the problem between the red lines.

I ll have to stop now, maybe tomorrow i ll come up with an answer.

I ll have to stop now, maybe tomorrow i ll come up with an answer.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

i think its the non ford pattern parts - take a bit more work to get them right

like i said when i did my pickup i didnt get it perfect

went from this to this but if you look close at the finished sill you can see that its not level

finished pic

but for this van i wasnt spending a lot of time making it perfect its too far gone - i just want a solid useable mk1

- i just want a solid useable mk1

like i said when i did my pickup i didnt get it perfect

went from this to this but if you look close at the finished sill you can see that its not level

finished pic

but for this van i wasnt spending a lot of time making it perfect its too far gone

-

Luke - Site Admin

- Posts: 44386

- Joined: Wed Mar 02, 2005 12:53 am

- Location: Rotherham, Yorkshire!!

Re: My Mk1 Transit's Restoration Project

keep up the good work m8

TRANSIT M8, SAY NO MORE YOUR IN...... FORD THROUGH TO THE BONE......

-

transitandy - Transit Extremist

- Posts: 17754

- Joined: Fri Nov 30, 2007 1:10 am

- Location: Essex...

Re: My Mk1 Transit's Restoration Project

from what I can see in the pic you may have to rebent the new footstep from the uper side ? to make it go lower down or I m mistaken.?

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Re: My Mk1 Transit's Restoration Project

Thanks transitandy  . No,redeemer

. No,redeemer  i think the only solution is they slant a bit at the end as long as the other side comes the same and the work is neat i don't mind. Though i have to go to Karmnu and see if he has encountered this problem, which i m sure he has.

i think the only solution is they slant a bit at the end as long as the other side comes the same and the work is neat i don't mind. Though i have to go to Karmnu and see if he has encountered this problem, which i m sure he has.

TRANSITS KEEP YOU GOING!!!, GOING!!! AND GOING!!!!!!

-

malta transit - Our man in Malta!

- Posts: 1057

- Joined: Sun Jun 03, 2007 2:13 pm

- Location: malta

Re: My Mk1 Transit's Restoration Project

Here I took some pics to show you my footstep of my mk2, it might be of help altough taking measurments in practice would be the best thing

if your footstep is an imitation, I think you should take care that the gap between the door and the footstep as viewed from outside must be parallel so it wount catch the mistake in the eye.

if your footstep is an imitation, I think you should take care that the gap between the door and the footstep as viewed from outside must be parallel so it wount catch the mistake in the eye.

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Re: My Mk1 Transit's Restoration Project

Opps I have uploaded them as avatars

here they are :

http://s290.photobucket.com/albums/ll26 ... IM0225.jpg

http://s290.photobucket.com/albums/ll26 ... IM0227.jpg

here they are :

http://s290.photobucket.com/albums/ll26 ... IM0225.jpg

http://s290.photobucket.com/albums/ll26 ... IM0227.jpg

1982 MK2 SWB 2.5 DI 5 SPEED 70PS now with turbo

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

1982 MK2 LWB PICKUP 2.5 DI 4 SPEED

-

redeemer - Transit Devotee

- Posts: 609

- Joined: Tue Dec 11, 2007 10:35 pm

- Location: Malta

Return to Members Transit's - Progress Reports!

Who is online

Users browsing this forum: No registered users